After the acquisition of Aurisonics by Fender, I had the honor of experiencing various responsibilities on the in-ear monitor packing team which consisted of the following –

- Eyes for detail: Accept or reject quality of assembled Fender Pro IEMs as necessary and send back any for repair. Observe, propose, and create effective strategies and solutions for production.

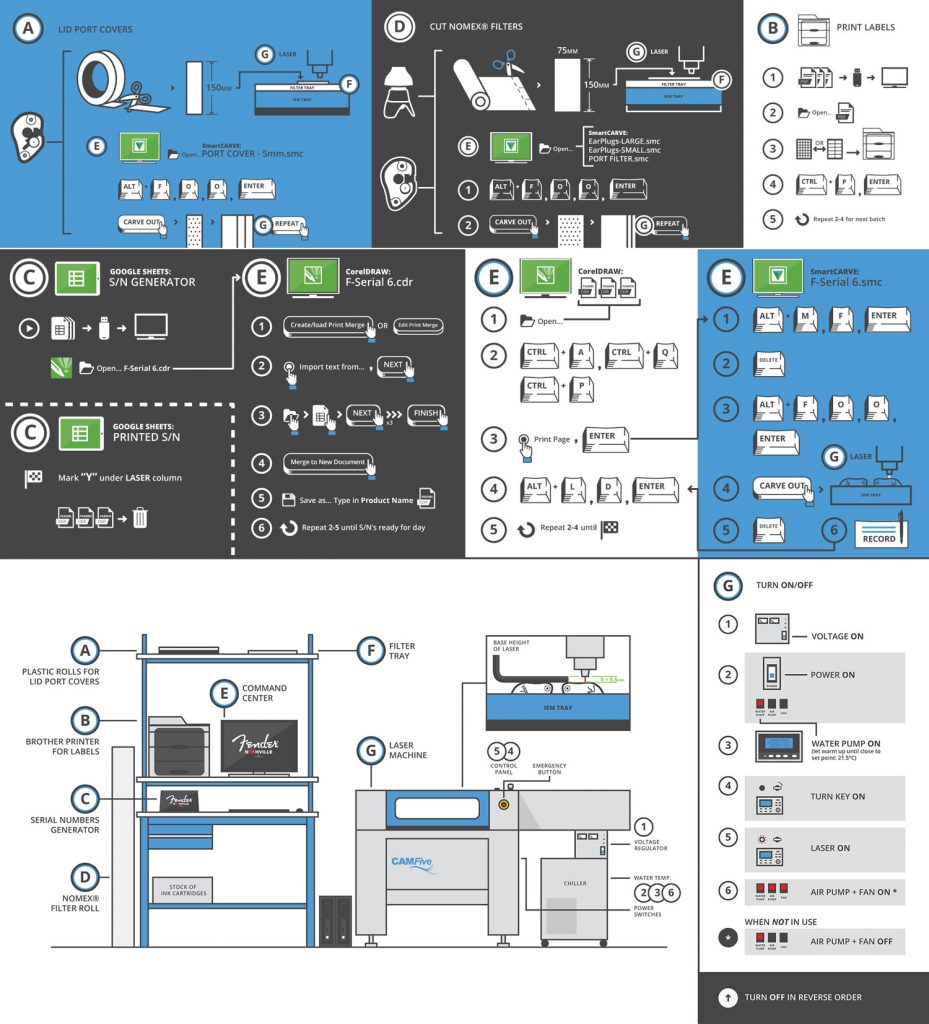

- CorelDraw, SmartCarve, + CAMFive Laser Machine: Engrave serial numbers onto IEMs and cut out filters for bass ports & ear plugs. Also, calibrate laser machine for new adjustments and jigs.

- Adobe Creative Suite: Provide & adjust packaging labels that need changes in copy and make various design adjustments if needed. Also, design manuals to teach teammates/trainees how to operate machines, create barcode labels, assemble IEMS, etc.

- Spreadsheets: Keep organized track of product serial numbers during lasering process

- Packing + shipping

With this experience and knowledge from production, I created an illustrated guide to operating the laser machine for the Nashville Fender team. I also created quick start guides for each new in-ear monitor before they entered the market.